Lab Equipment

Gunt PT500 / PT500.05

Gunt RT360

Gunt RT370

Gunt TM182

Roland MDX-40A Milling Machine

With the MDX-40A, students can produce high-quality product prototypes right at their desktop. Support for G-code NC programming language makes the MDX-40A well suited for both professional and educational applications.

Rotary Axis Unit for Larger Applications

In addition to a flat work table, the MDX-40A features a rotary axis unit that supports

larger materials. Students can mill a 500ml (16.9oz.) PET bottle. Objects can be milled

at any angle from 0 to 360 degrees.

3D Print Lab

Our dynamic 3D print lab includes: (4) MakerBot Replicators, (1) Mini Compact 3D Printer, (1) XL MakerBot Replicator Z18 3D Printer, MakerBot Digitizer 3D Scanner and (1) Markforged II carbon fiber/kevlar/fiberglass 3D printer.

Whether students are rapid prototyping or reverse engineering the 3D print lab offers first hand experience in 3D file management and production.

Ceaform 3D Scanners

Our lab includes: (2) professional Creaform 3D scanners that are a portable 3D scanning experience, providing fast and reliable measurements. With these handheld 3D scanners, you can even capture 3D data in full color.

Through a very efficient process, these self-positioning systems will provide visual guidance as you are scanning. Their innovative technology bypasses preparation steps and specific setups, provides a very fast measurement rate, and does not require manual data post-processing.

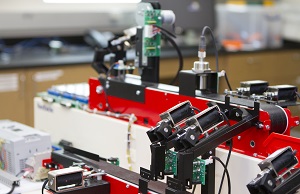

Feedback PLC Workcell 34-120

The Dual Conveyor Workcell combines a parts selection task with an assembly process. This then enables in depth study of PLC’s being used in process control systems. Students are required to consider in more detail the structure of control systems.

More complex control scenarios can be developed using combinations of timers and counters with master and zone control functions. The unit is fully self-contained comprising a power supply, interface unit and a range of sensors and solenoid actuators.

The interface circuits allow the conveyor system to be operated from any standard industrial PLC system using 24 V dc logic levels. There is space within the interface board to drive additional detectors.

SMC MAS-200 Mechatronics

Amatrol 87-TMS

Gunt Hamburg WP 300 Universal Material Tester

This material tester is a benchtop unit for training purposes. Simple operation and robust construction make the unit suitable for student experiments.

The test spectrum for the basis unit covers tensile tests, and also Brinell hardness testing. Additional bending, shear, cupping and compression tests can be performed. PC data acquisition and evaluation is also possible.

Gunt Hamburg FL 100 Strain Gauge Measurement

![]()

Strain gauges are used extensively in sensor systems to detect forces, moments and deformations. The FL 100 provides a wide-ranging introduction to the fundamentals of measurement by strain gauges. Three test specimens for tension, bending and torsion are each fitted with four strain gauge measuring points. The strain gauges are wired in the full bridge. The specimens are loaded incrementally allowing for the strain reading to be sequentially monitored.

Gunt Hamburg 1A 110 Sensor Calibrator

The IA 110 is used to calibrate an electronic pressure sensor under practical conditions. The test pressure is generated with a conventional piston manometer. The piston is loaded with weight rings and generates a defined test pressure.

GUNT PT500 Machinery Diagnostic Machine

The PT 500 permits vibration measurement exercises (measurement of vibration displacement, velocity and acceleration in the time/frequency range). Field balancing of rigid rotors and alignment of shafts can also be practiced.

The key components of the unit are the mechanical elements (clutch, bearing blocks and shaft with rotors), the drive motor with variable speed via frequency converter and tachogenerator, and the display and control unit with digital displays for power output and speed.

Amatrol Programmable Logic Controller (PLC)

The Amatrol Programmable Logic Controller (PLC) is heavily used by many industries. When programmed properly, the PLC can eliminate human error from the manufacturing process. As the students become trained on the methods used for programming the logic into microprocessors, they can apply the skill sets to any utility or private manufacturing industry of the world.

Amatrol T7017 AC/DC Electrical Systems

The Amatrol T7017 AC/DC Electrical system is a unit that allows students to discover the ways and methods of controlling electricity through the use of electronics. The T7017 experiments with both forms of electricity, Alternating Current and Direct Current. This unit lays the foundational ground work for T5552, T5553, Control Valve, and PLC.

Lucas Nulle Wind Turbine Training System EWG1

Wind turbine simulator is designed for investigating modern wind power plants incorporating Double-Fed Induction Generators (DFIG). The wind can be emulated realistically by means of a serve machine stand and WindSim software. Connected PC and TV monitor, and associated multimedia course, impart theory in addition to supporting experiment procedures and evaluation of measurement data. The set contains Interactive Lab Assistant (support for multimedia instructions, assessment tools, virtual measurement instruments), wind emulator (permits precise laboratory simulations of conditions prevailing at a real wind power plant through realistic emulation of wind and airfoil geometry, control of pitch and wind strength, and specification of wind profiles), and double-fed induction generator with control unit (allows generator control in sub-synchronous and super-synchronous modes, automatic control of active and apparent powers, frequency and voltage, manual and automatic synchronization, and measurement and display of all system variables). Benefits are the accurate emulation of wind power and mechanical design of wind power plants, detailed usage of servo machine test stand, user-friendly operations using microcontroller-operated control unit of DFIG, and integration of state-of-the-art technology in classroom learning.

Lucas Nulle Electric Power Distribution Double Busbar System Trainer

Electrical power at large switching stations is distributed mostly using double busbar systems. These stations incorporate switching matrices for connecting two busbars, the incoming and outgoing feeder cubicles as well as measurement fields. The incoming and outgoing busbar cubicles and switching matrices are furnished with circuit breakers and a disconnector for each busbar terminal. For safety reasons, a particular switching logic must be strictly adhered to here. The double busbar model incorporates all functions of practical relevance. Integrated instruments for measuring currents and voltages permit direct analyses of switching operations. Devices are monitored and controlled by means of SCADA system.

Marcraft Smart Grid GT-7000 Training System

Marcraft Smart Grid Technician training system utilizes in-home ZigBee based Smart Grid training system for peak-power shaving, efficiency, real-time pricing. It supports training in the power demand response and power storage management, Smart Grid communications, meter management systems, Smart Meters, support for demand and automated adjustment, and dealing with renewable generation.

Small Wind Turbine System

The small wind turbine system consists of two 1kW ARI Wind Generators, connected to a battery bank through charge controllers. The battery bank is then connected to the inverters, which feed the stored energy back to the building's power grid. It is connected through a Smart Meter so that the energy produced can be easily monitored in real time and displayed on a web site. Students learn all of the aspects of small wind energy production, from generation, to battery storage, to grid connection.

Solar Photovoltaic System

Solar photovoltaic system consists of 12 solar panels array (Sun SV-T-195W panels each) connected to a battery bank through charge controllers. The battery bank is then connected to the inverters, which feed the stored energy back to the building's power grid. It is connected through a Smart Meter so that the energy produced can be easily monitored in real time and displayed on a web site. Students learn all of the aspects of small solar panel array production, from PV generation and technology, to battery storage, to grid connection. Together with the Small Wind Turbine System, students can learn the similarities and differences between different renewable generation systems, their advantages and disadvantages.

Biofuels Technology Learning Lab

The Biofuels Technology Learning Lab has the BioPro 190 and Ethanol Distillation System by Haney Enterprises.

The BioPro 190 is a compact stainless steel industrial-grade automated biodiesel processor that is capable of converting up to 50 gallons of organic oils into 40 gallons of biodiesel using a base-catalyzed chemical reaction. The original material, such as used cooking oil, animal fat or fresh vegetable oil, is thus chemically altered, and the resulting biodiesel can run efficiently in an unmodified diesel engine.

The Haney Enterprises Ethanol Fuel Distillation System comes complete with a 60 gallon boiler, 6-plate Distillation Column, 50 gallon fermenter, heating element and control, agitator, transfer pump, and yeast. This system is capable of producing fuel at 90%-92% alcohol by volume at one gallon an hour. The heating element is 5500w/220v with a controller allowing immediate boiler temp adjustments. The boiler is insulated with polyurethane and a 304 stainless jacket. It is constructed entirely of 304 stainless, mirror polished inside and out. All fittings are stainless sanitary fittings using tri-clamps for attachments. This system comes with or without an air operated, explosion proof, agitator which attaches on top of the boiler for circulating the ferment during distillation. The column is a 6-plate full reflux column with a reflux condenser on top leading into a final condenser on the side. It uses an attached parrot’s beak allowing a constant monitoring of alcohol content through-out the entire distillation process. The fermenter is constructed of 304 stainless steel with all stainless sanitary fittings. It is mirror polished inside and out and has a 50 gallon capacity. The system we have put together will include a pump for transferring ferment from the fermenter to the boiler, also included is 22lbs of ethanol yeast. By using electric heating as opposed to gas safety is increased exponentially, as there is no chance of the volatile fuel being made coming in contact with an open flame. Thus the system is an open vapor management system designed to control / prevent pressure to build inside itself.

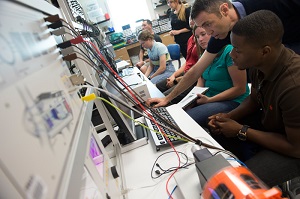

Circuits / Electronics / Microprocessors

Fully equipped lab for circuits, electronics, digital logic and microprocessors experiments. It consists of breadboards, various active/passive components for circuits, relays, filters, power supplies, function generators, oscilloscopes, soldering stations, DMMs – full equipment for all possible circuits and electronics experiments and small developments. Assembly and C language programming centered on analogue and digital I/Os on Freescale 68HC12 development boards. It also contain National Instruments NI ELVIS II boards with LabView for circuits simulations. From circuits and electronics experiments on NI Elvis II boards with NI Multisim, to programming using NI LabView centered on I&C, to using myDAQ systems for real-life data acquisition and control, to myGrid mini systems for Smart Grid, we use NI tools fully integrated in multiple courses for hands on development and applicable real-life skills.

Instrumentation Lab: Measurement, Data Acquisition and Calibration

![]()

Industrial Tools Lab

General Lab Supplies

Our lab supplies and various tools allow us to conduct all kinds of experiments in electrical power technology and to provide students with materials, tools, and environment in which they could build great projects and put their knowledge to work: from Smart Grid OSI PI System projects, to electric golf cart conversions, to solar-powered homes, to solar tracking devices, to hybrid solar-wind projects!